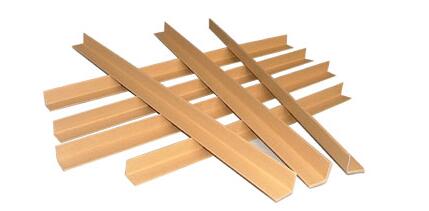

纸护角的应用极为广泛,包装、封装展现了其的价值所在,那么它的生产流程是怎样的?有没有严格的质量把关?

The application of edgeboard is very wide, packaging, packaging to show its value, then its production process is what? There is no strict quality checks?

纸护角生产流程,独立上纸架 挂纸部分。可根据客户要求的纸张的层数决定上纸架的数量;

The angle of paper production process, independent paper rack hanging paper part. According to customer requirements of the number of paper to determine the number of paper;

涂胶部分

Glue part

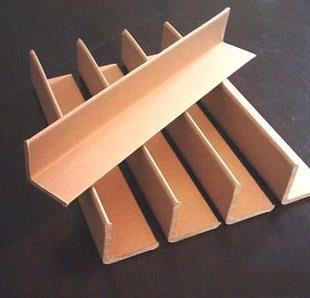

1.纸护角有多种涂胶方式可供选择;

1 paper corner has a variety of options for glue;

2.如单面涂胶、双面涂胶、淋胶式涂胶等;

2 as single glue, double-sided adhesive, glue pouring type glue etc.;

3.一般采用转移式自动涂胶,涂胶厚度可由刮刀 随意调节;

3 commonly used transfer type automatic coating, coating thickness can be adjusted by a scraper;

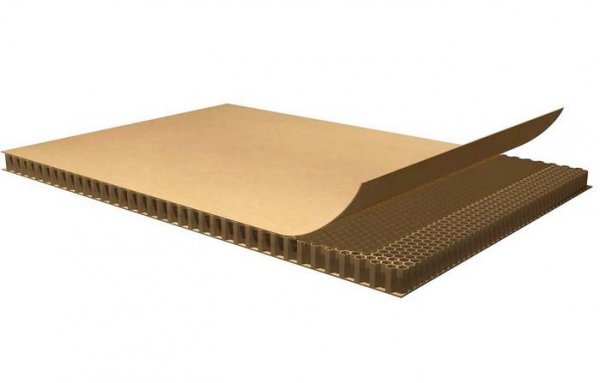

胶水 包边调节部分:多组辊轮调节各层纸张,在变换纸护角规格时可快捷、 方便低调整,贴合准确;面纸自动包边,可选择半包或全包的包边形式, 生产出来的产品外形美观。

Glue edge adjusting part: Group roller adjusting the layers of paper, transform paper corner protector specifications can be fast and convenient low adjustment, accurate fit; tissue automatic wrapping, wrapping form of half a pack or all inclusive, production out of the product appearance.

成型部分:压轮模具对纸张进行高强度的碾压成型

Molding part: press wheel mold to carry out high strength roller compaction

传动部分:采用大功率交流电机驱动,配变频器控制电机运转;

Driving part: using high power AC motor drive, with inverter control motor running;

压轮与 电机间采用减速器及传动轴连接,各个压轮同步转动,运转平稳;

The press wheel and the motor are connected with a speed reducer and a transmission shaft;

分切部分:机器上配的纸护角裁切机有气动式,采用高硬度锋钢刀片裁 切,分切准确、平稳,切割面平整美观;

Cutting part: pneumatic machine with angle of paper cutting machine, by high hardness front blade cutting cutting, slitting accurate and stable, smooth cutting surface appearance;